| Anber Wire Mesh & Machine Factory |

|

Manufacturer of Wire Mesh and Wire Mesh Machine: expanded metal machine, angle bead machine, its finished products, etc. |

-

Wire Mesh Machine

- Welded Wire Mesh Machine

- Truss Girder Welding Machine

- Wire Drawing Machine

- Angle Beads Machine

- Plaster Stop Machine

- Brickwork mesh Machine

- Rib Lath Making Machine

- HY-Rib Mesh Machine

- Expanded Metal Mesh Machine

- Barbed Wire Machine

- Hexagonal wire netting machine (Gabion mesh machine)

- Chain Link Fence Machine

- PVC coating line

-

Wire Mesh Products

- Welded Wire Mesh

- PVC Coated Wire

- Angle Beads (Corner Beads)

- Plaster stop

- Brickwork reinforcing mesh

- RIB LATH

- HY-Rib Formwork Mesh

- Hexagonal Wire Netting

- Expanded Metal Mesh

- Barbed Iron Wire

-

Anber Contacts:

Tel: +86-510-88239310

88239309

| Home page | Wire Mesh machine | Mesh welding machine | PVC coating line | Online Order | Contact Us |

Expanded metal mesh Machine:

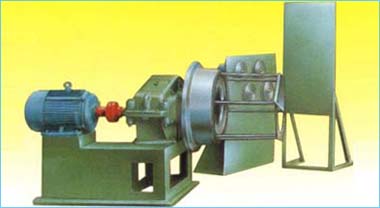

The full wire drawing production line need many kinds of auxiliary machines, such as

|

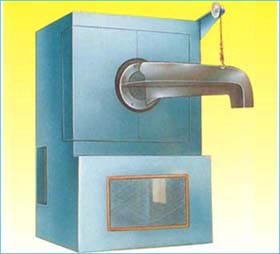

This wire unloading machine is most idea for final process of screw wire.

|

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

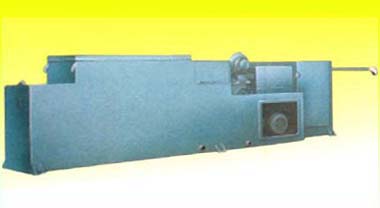

| This Wire Straightening & Cutting Machine utilizes the principle that the wire will be straightened while rotating at high speed and being drawn at the same time. The machine consists of two units of straightening roller and Set-Length &Cutter Seat. Metal is moved by feeding roller, straightened by straightening roller, and taken into the Set-Length & Cutter Seat by Outlet Feeding Roller. The set-length & cutter seat consists of the thread stripper and cutting arm. When the wire is taken into the feeding roller, the straightening roller revovled, a counter will count the quantity and the cutting length, then the cutting rod makes the tread stripper moved and the finished products will fall into the collector.

|

Our Wire Mesh Machine Products Catalog:

Our Wire Mesh Products Catalog:

| • Welded Wire Mesh | • PVC Coated Wire | • Corner Beads (Angle Beads) | • Plaster stop |

| • HY-Rib Formwork Mesh | • RIB LATH | • Hexagonal Wire Netting | • Expanded Metal Mesh (Diamond Metal Mesh) |

| Anber wire mesh machine | Anber Expanded Metal Mesh Machine | Rib lath machine | Mesh welding machine | Wire drawing machine |